Shot qarxinta iyo habka deminta ee jir meel birta ah

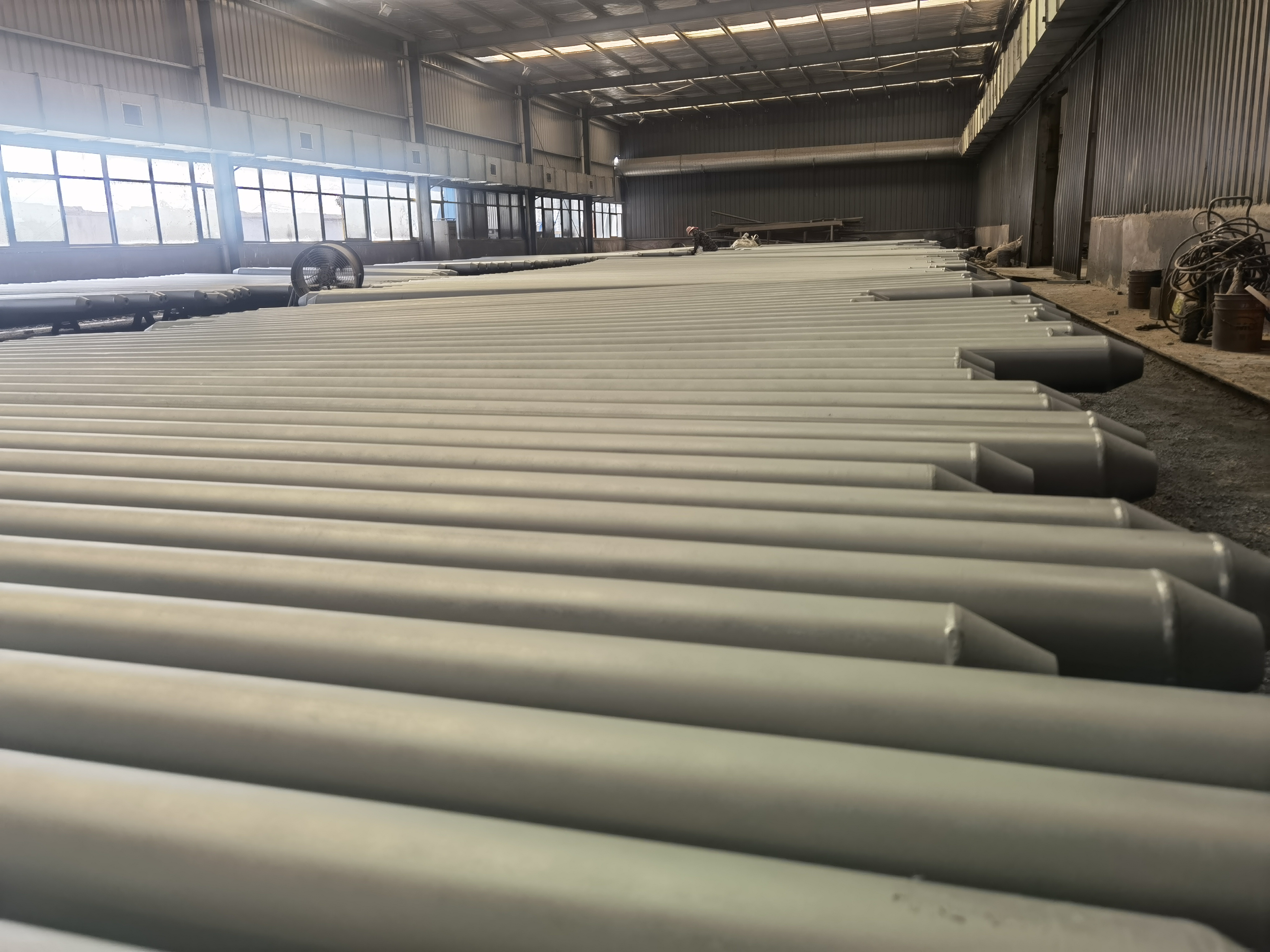

Xabad qarxin:

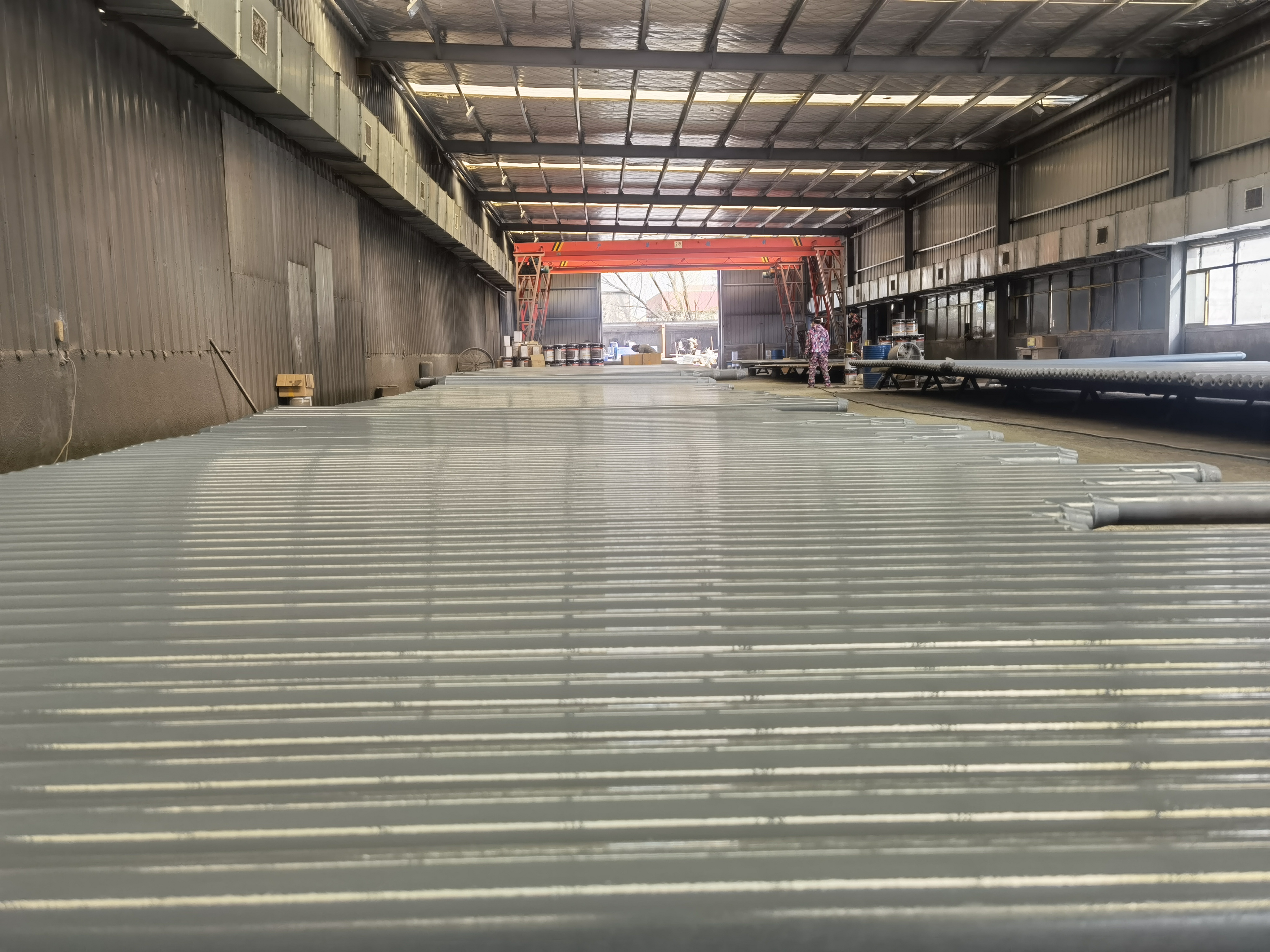

Rasaasta qarxinta waa in la isticmaalo xoogga centrifugal ee mashiinnada wax qarxinta marka uu ku wareego xawaare sare, habka qarxinta rasaastuna waa mid aad u sarreeya.

Xawaaraha tooska ah ee birta ayaa lagu toogtaa dusha sare ee birta si loo daweeyo, taasoo ka dhalata afuufo iyo saamayn shiidid, miisaanka oksaydhka ee dusha birtana waa la saaraa.

iyo miridhku, oo waxay soo saaraan qallafsanaan gaar ah.Rasaasta qarxinta ayaa ah mid aad waxtar u leh waxaana lagu samayn karaa jawi xiran.

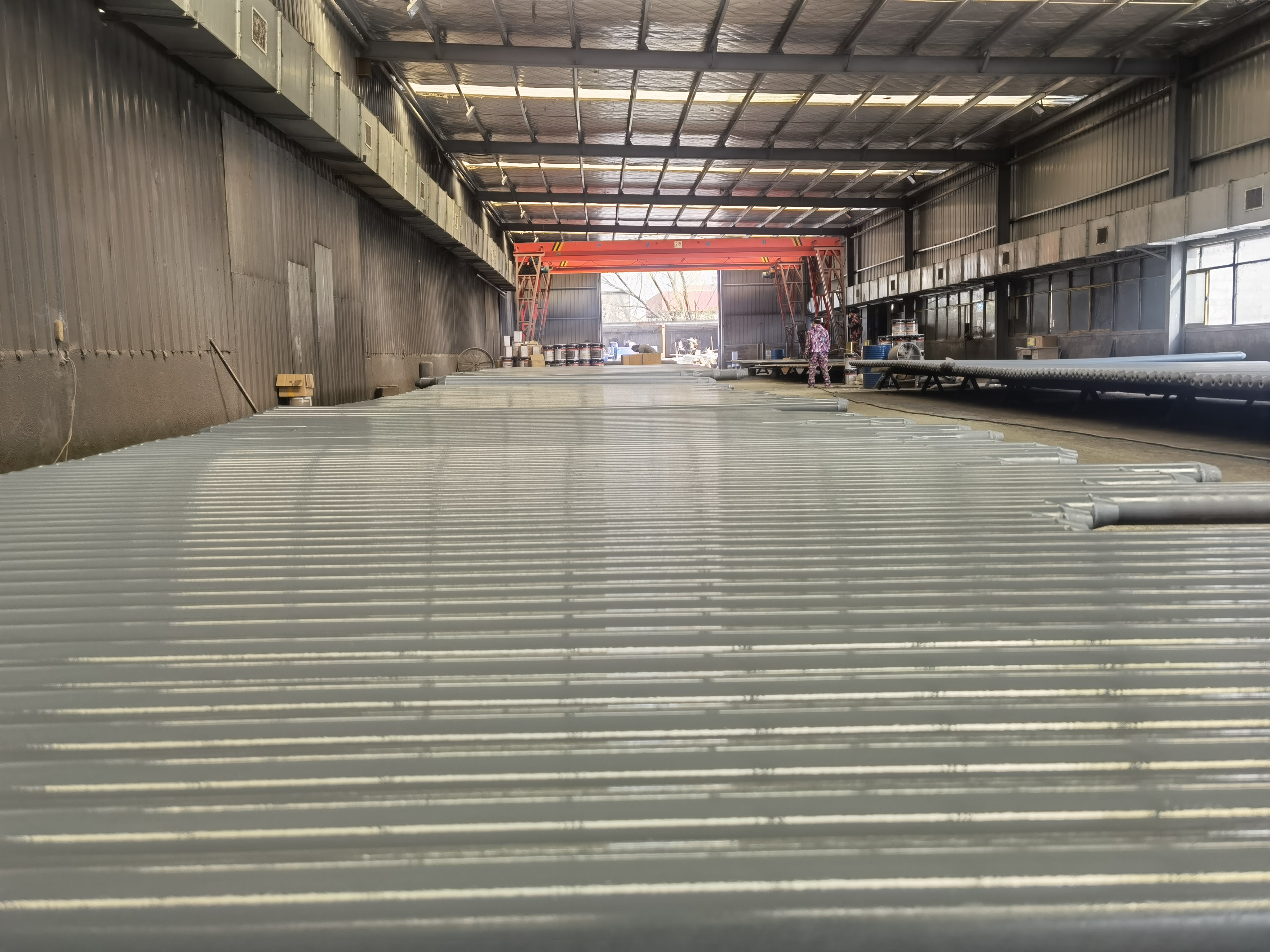

Heerka qarxinta xabada iyo miridhku;

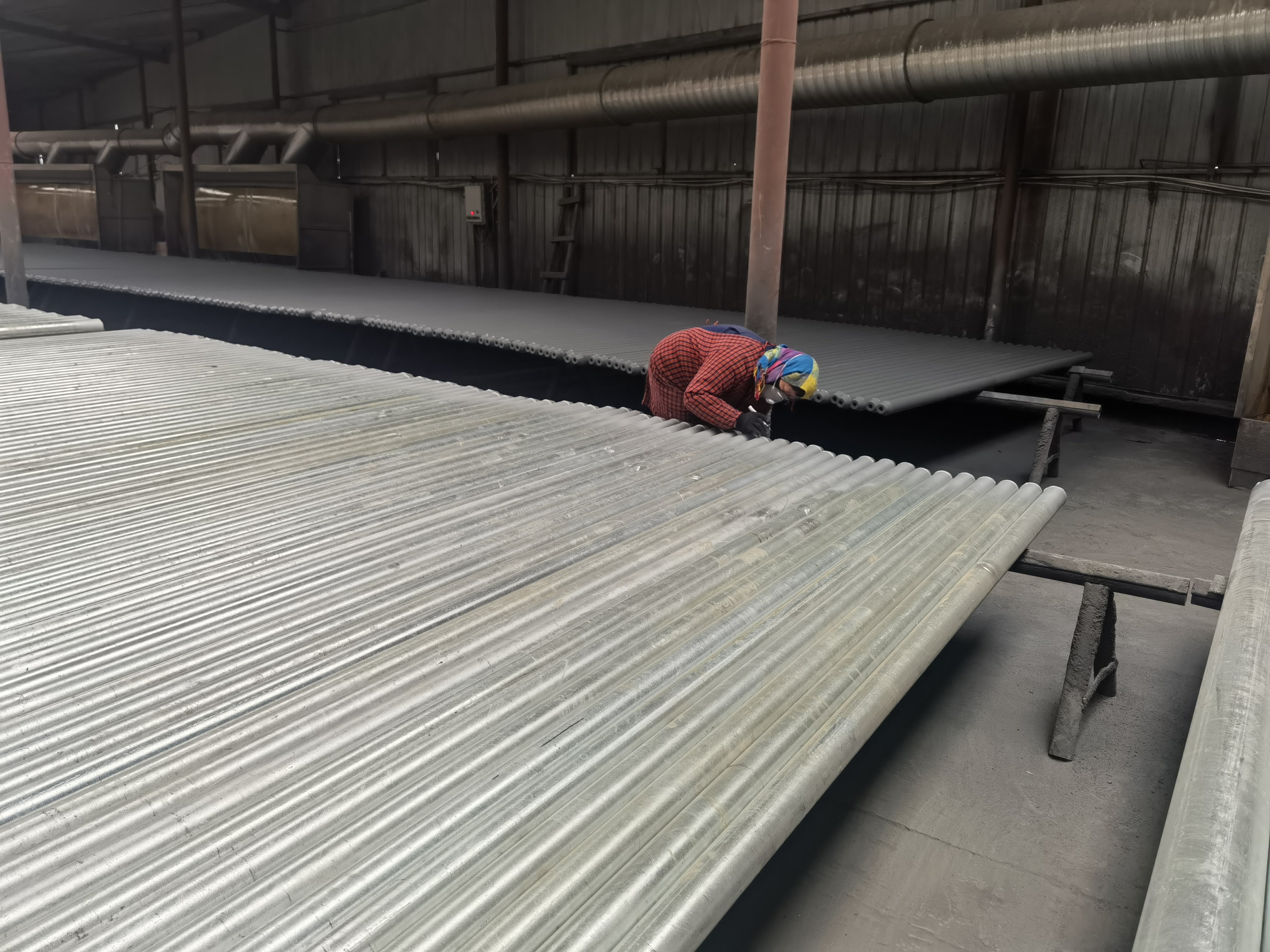

(1) Rasaas yar oo qarax ah iyo ka saarista miridhku.Dusha birta ahi waa inay ahaataa mid aan lahayn dufan ama wasakh la arki karo oo aan lahayn miisaan adag oo oksaydh ah, miridhku iyo dahaarka rinjiga iyo lifaaqyada kale;

(2) Rasaas si fiican u qarxisay iyo ka saarista miridhku.Dusha birta ahi waa inay ahaataa mid aan lahayn dufan ama wasakh la arki karo oo aan lahayn miisaan adag oo oksaydh ah, miridhku iyo dahaarka rinjiga iyo lifaaqyada kale;

(3) Toogasho aad u qoto dheer oo qarxin iyo ka saarida miridhku.Dusha sare ee birta waa inay ahaataa mid aan lahayn dufan la arki karo ama wasakh, miisaan, birta ku xiran sida miridhku iyo dahaarka rinjiga, wixii raad ah ee soo haray waa inay ahaadaan wasakh yar oo kaliya oo ah qaab dhibco ah;

(4) Rasaasta qarxinta iyo saarista miridhku si dusha birta looga dhigo nadiif.Dusha birta ahi waa inay ka madax bannaanaato dufan muuqda ama wasakh, maqaarka oksaydhka, miridhku iyo daaha rinjiga iyo waxyaalaha kale ee ku lifaaqan, oo muujinaya dhalaal macdan labis ah;